Aluminum sand casting is a common aluminum alloy casting process that uses quartz sand as the main raw material to prepare sand molds. It employs gravity pouring techniques and can produce aluminum alloy components of various shapes and complexities. This method is characterized by high production efficiency and simple processes.

In terms of casting technology, VG engineering utilizes advanced casting equipment such as furnaces and casting machinery to ensure complete melting of the aluminum alloy material and maintain stable temperature and fluidity during the casting process. Throughout the casting process, workers need to adjust parameters such as pouring speed and temperature according to the product requirements to ensure that the dimensions and quality of the products meet the specifications.

Our aluminum sand cast products are exported to America, Europe and Asia market, including auto components, furniture components, Lighting components, Pump & Valves components, architectural components and so on.

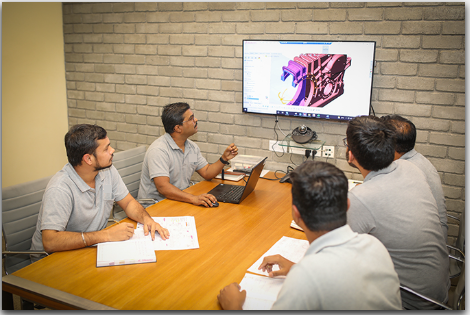

Our team of well-trained and experienced engineers conceptualise, design and develop products that meet the varied requirements of your business. We have a dedicated design facility that is equipped with the latest Computer Aided Design (CAD), Computer Aided Engineering (CAE) and Computer Aided Manufacturing (CAM) software from SOLIDWORKS and Siemens. The combination of powerful software and a creative engineering team allows us to overcome design challenges, improve casting practices and ensure that we deliver 100% on design goals and customer satisfaction.

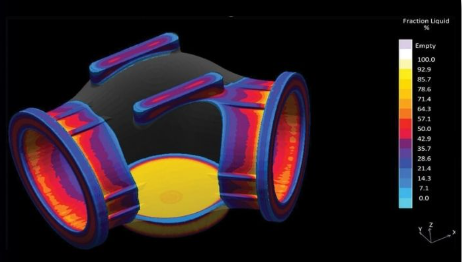

In addition to design and development, our engineering team is highly skilled at offering solutions to optimize the casting process. our engineers analyze and predict the behavior of molten aluminium in advance. This helps us limit any and all kinds of casting defects, and allows us to drastically reduce the time taken to make the golden sample, create the completely finished component and scale up as needed, all with the least number of trials. In turn, this enables production at cost and at scale.

We have in-house pattern making equipment that combines both conventional and modern technologies. Using 2D drawings and 3D design models, we manufacture moulds in a wide range of materials like wood, epoxy and resin as well as assorted aluminium tools with minimum lead times. Our pattern shop also has a fully automated mobile racking system that maximises our storage capacity, increases efficiency, improves handling capacity and provides quick access to stored patterns.

we’ve perfected the art of moulding and pouring aluminium. Our resin-bonded, no-bake sand casting process is flexible and cost-effective, allowing us to cast products with intricate designs ranging from 5 kilograms to up to 500 kilograms. With the latest technology and a semi-automatic loop line for moulding and pouring aluminium, we perfectly cast different grades of aluminium alloys according to your unique specifications

Casted aluminium that’s removed from the mould usually has slight imperfections. At VG Enggineeing, to maximize finesse, we put all of our castings through an extensive fettling process, where we remove excess material and ensure that the product precisely matches the intended dimensions. The castings are then shot-blast to smoothen out the rough surfaces evenly and enhance the product’s stress resistance. Finally, the castings are loaded onto high-tech furnaces for heat treatment to improve the mechanical properties of the aluminium. Having all the necessary equipment and skilled workforce for fettling and heat treatment in-house gives us an edge over the competition, allows us to drastically shorten delivery times and helps maintain high quality standards.

Our in-house machining facility is equipped with advanced CNC equipment like Horizontal Machining Centres (HMCs), Vertical Machining Centres (VMCs) and turning centres. With our high-tech machining tools, we strive to and have succeeded in achieving close Geometrical Dimensioning & Tolerances (GD&T) that are exceptionally precise. And thanks to modern technologies like the zero-point clamping system and multiple pallet system, we even keep the lead times short.

We also provide packing solutions for logistics via land, air and sea transportation systems. Our packing and logistical services adhere to domestic and international packing standards. With the latest equipment and technological knowhow, we ensure that the final products are packed in rigid and secure containers that are designed to keep the contents safe from various transit risks — including water damage, shock or impact due to mishandling, and vibrations from travel on uneven terrain.

| Process | Sand Moulding - Manual |

|---|---|

| Present Production | 120 MT Per Month |

| Spare Capacity | 50 MT Per Month |

| Maxi. Weigth Of Single Piece Casting | 0.250 to 300 Kilogram |

| Single Piece Size | 1200x1200x1200mm MAX. |

| Material | LM2, LM4, LM5, LM6, LM09, LM12, LM13, LM16, LM20, LM21, LM22, LM24, LM25 & Any Special metal in Al. Family. |

| Inspection & Testing Facilities | Spectro Analysis, Mechanical Testing, Hardness Testing's, Impact Testing’s, Micro Tests, Coating & Anodize plant, All NDT Like RT, UT, MT, DT Etc. |

| Sector To Supply | Automobile & Automotive, Aerospace, Defence, Electrical & Electronics, Lighting, Solar Industries, Marine, Medical, Rail & General Engineering Industries |

Aluminum sand casting is the process of forming aluminum into a mold pattern formed in sand. Almost 60 percent of all metals are produced using the sand casting process.

Aluminum sand casting typically uses green sand, bentonite clay, water, and aluminum alloys.

At VG Engineering, every casting undergoes a rigorous multi-stage quality control process, including advanced testing and inspection. Our quality assurance measures ensure that each product meets or exceeds industry standards for precision and performance.