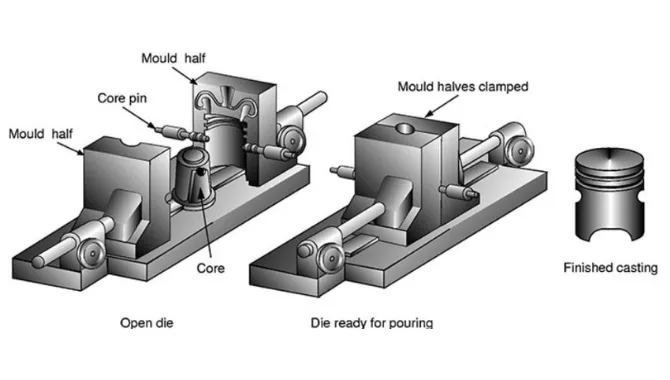

Gravity die casting is a casting manufacturing process that creates defined, textured or smooth-surfaced metal components. It allows molten metal to solidify in a permanent mold under the influence of gravity. This method is known for producing high-quality parts with more precision and better mechanical properties compared to sand casting due to the faster cooling rates and the use of durable molds.

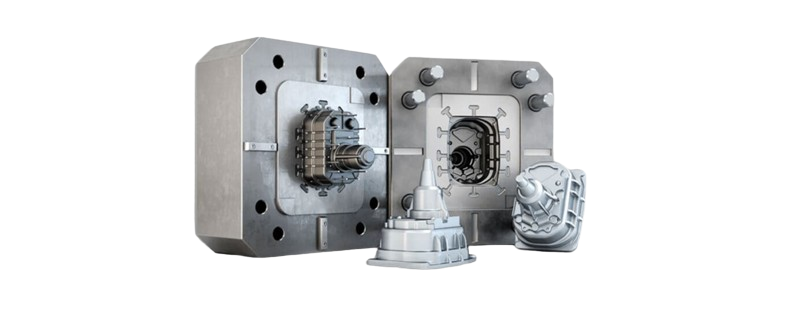

At the heart of this process is the precision-engineered die, which is typically made from steel or cast iron, and designed to withstand the high temperatures of molten metal repeatedly. Unlike other casting methods that use high-pressure techniques to fill the mold, gravity die casting relies on earth’s gravity to draw the molten metal into the die cavities.

The main advantages of this method include the ability to maintain a consistent thickness, a smooth cast surface that requires minimal finishing, and an increased production rate with the potential for automation. Gravity die casting is particularly well-suited for medium to high-volume production runs, making it an ideal choice for the automotive, aerospace, and other industries, where precision and durability are required. To transform molten metal into precise, durable components, the complete gravity die casting process involves several critical steps . Here is a detailed step-by-step guide from raw material to finished product at VG Engineering

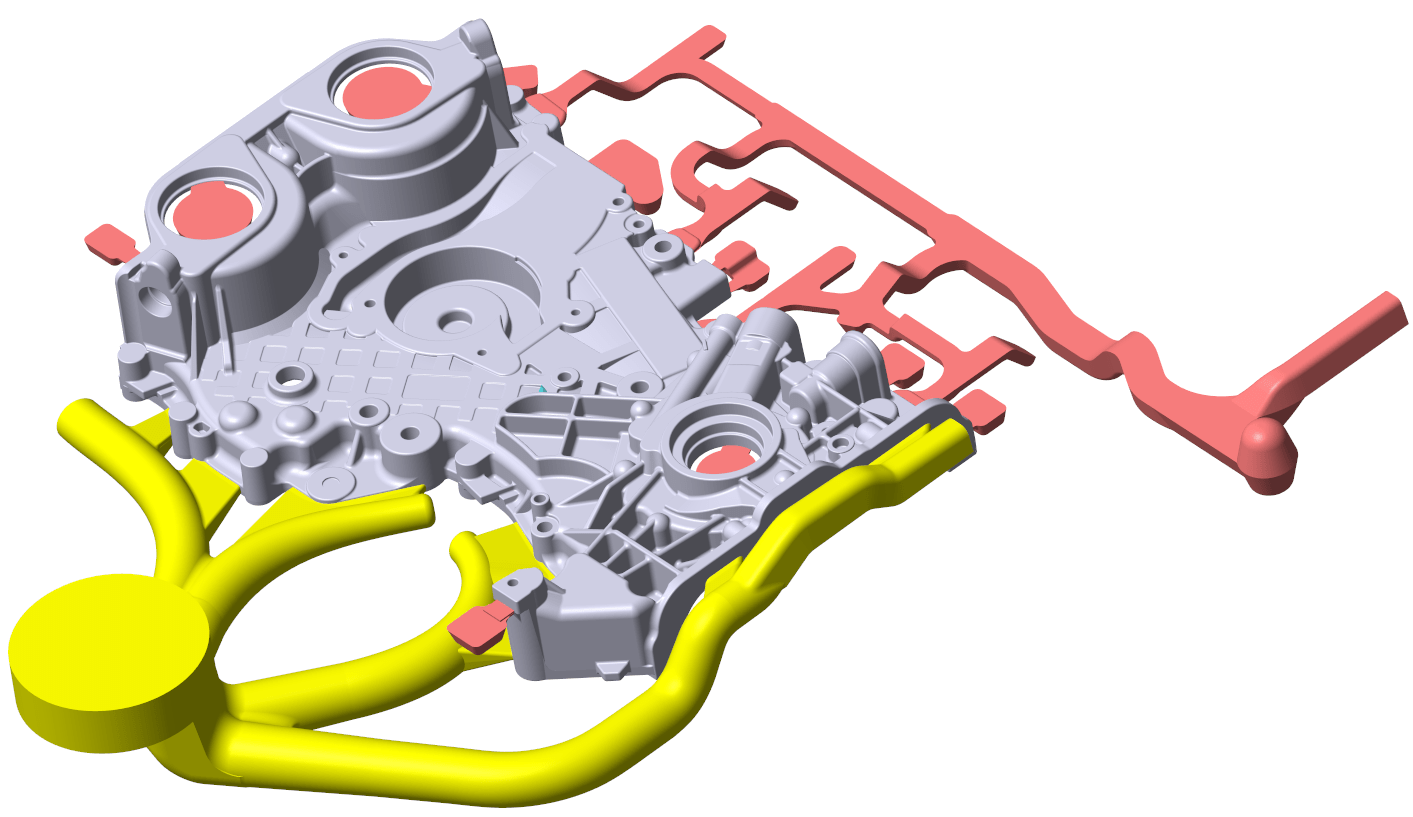

Main objective of using computer-aided casting design and simulation software to casting process is to offer maximum data on casting quality by predicting solidification occurrences and associated features which can be helpful to get an optimum level cast part soundness with maximum defect free component.

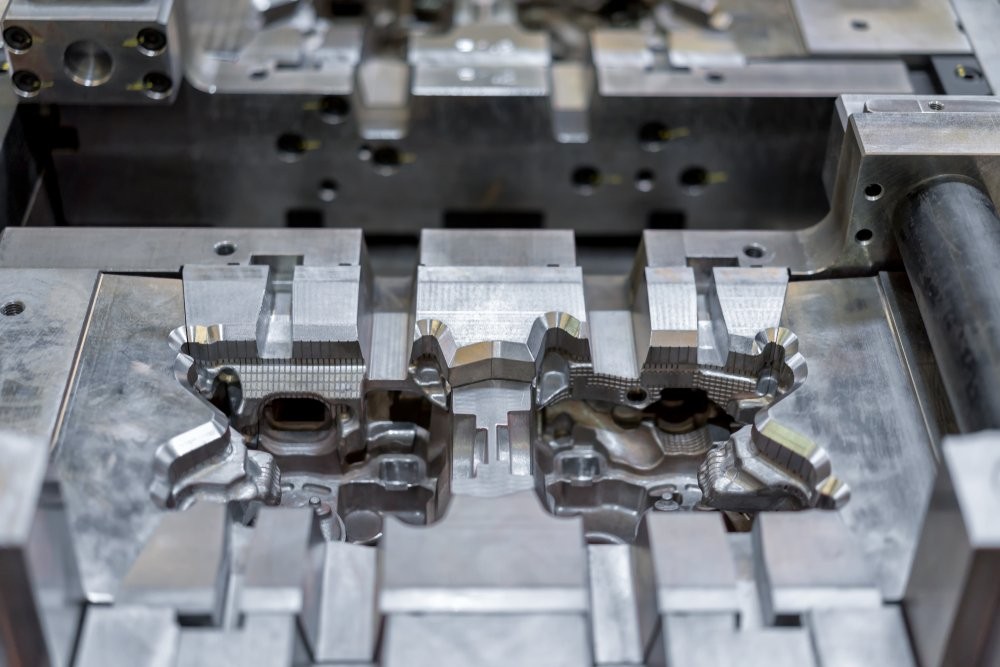

The initial stage of gravity die casting involves the preparation of the die, which is essentially a high-quality mold typically made from steel or cast iron. The design of the die is important as it affects the shape, surface finish, and dimensional accuracy of the final casting. At CFS Foundry, the dies are designed using advanced CAD software and then precision-engineered to meet the specific requirements of each project. Special attention is given to the thermal characteristics of the die to ensure it can manage the heat effectively during the casting process.

Before pouring the molten metal, the die is preheated to a specific temperature. This step is critical to ensure the longevity of the die and to prevent premature solidification of the molten metal. Preheating also aids in better metal flow and can reduce porosity and shrinkage in the final product. CFS Foundry carefully monitors and controls the temperature to optimize the casting quality and extend the life of the die.

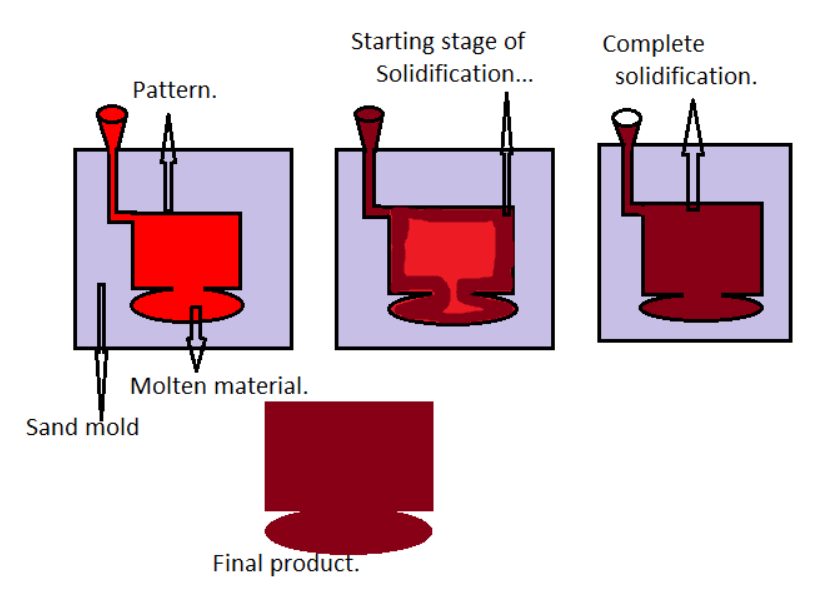

With the die at the proper temperature, molten metal is carefully poured into the die cavity. The metal is prepared in a separate furnace where it’s heated until it reaches the correct liquid state. The skillful pouring is vital to control the flow rate, which can lead to defects in the casting. Our foundry ensures that the pouring process is conducted under controlled conditions to maximize the integrity of the cast parts.

Once the molten metal is in the die, gravity pulls it into every crevice and corner of the mold. As the metal cools, it begins to solidify from the outer edges of the die cavity moving inward. Cooling systems can be applied to certain areas of the die to accelerate solidification in those regions, ensuring a consistent cooling rate and minimizing the risk of defects. The time taken for the metal to solidify completely will depend on the complexity and size of the casting as well as the metal used.

After the metal has fully solidified, the die is carefully opened. At CFS Foundry, state-of-the-art machines are employed to open the dies and eject the castings. This is done with precision to avoid damaging the casting or the die. The newly formed component, which now bears the detailed impressions of the die surface, is then removed and inspected briefly before moving to the next stage.

The final step in the gravity die casting process is the trimming of excess material, which includes the removal of feeders, runners, and any flash that occurred during the casting process. CFS Foundry utilizes both manual and automated methods for trimming to ensure a clean finish. Following this, the cast parts may undergo additional finishing processes such as sanding, grinding, or shot blasting to achieve the desired surface texture. Depending on the client’s specifications, further treatments like painting, powder coating, or anodizing may be applied.

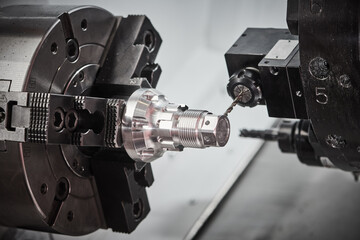

Various machining techniques are then employed including CNC or VMC or HMC or VTL or SPM to achieve the final surface finish & dimensions needed to more important with function, fitment & application area point of view then after with all quality checks & approval before dispatch.

Part will be done with standard or customized packaging systems to make a shipment on desired location by customer, from the beginning level incoterms has been already set for the goods dispatch and clearance of the shipment with particular system & Process.

| Process | Die Molding – Manual |

|---|---|

| Present Production | 100 Mt Per Month |

| Spare Capacity | Few Kg To 55 Kg. Per Piece |

| Single Piece Size | 800x800x800mm |

| Material | LM6, LM9, LM13, LM20, LM25 Any Special Metal In Al. Family |

| Inspection & Testing Facilities | Spectro Analysis, Mechanical Testing, Hardness Testing's, Impact Testing’s, Micro Tests, Coating & Anodize plant, All NDT Like RT, UT, MT, DT Etc. |

| Sector To Supply | Automobile & Automotive, Aerospace, Defence, Electical & Electronics, Lighting, Solar Industries, Marine, Medical, Rail & General Engineering Industries |

Gravity Die Casting is a process where molten metal is poured into a mold using the force of gravity, rather than high-pressure injection. This method ensures a controlled flow of metal, resulting in components with excellent structural integrity and minimal defects.

Gravity die casting is best suited to alloys with low melting points. Aluminum is the most commonly used material, accounting for over 80% of all die-cast parts. So, We are work with high-quality aluminum alloy.

At VG Engineering, every casting undergoes a rigorous multi-stage quality control process, including advanced testing and inspection. Our quality assurance measures ensure that each product meets or exceeds industry standards for precision and performance.