We are a trusted name in the aluminium section manufacturing industry since 2015, specializing in the manufacturing of high-quality extruded aluminium products. With an ISO 9001:2015 certification and over 25 years of experience, we have established ourselves as a leading aluminium section manufacturing company in India in a very short span of time. Our state-of-the-art manufacturing facility in Gujarat-INDIA, enables us to produce a wide range of extruded aluminium products that cater to various industries.

we pride ourselves on our commitment to innovation and sustainability. Our team of experienced professionals works tirelessly to ensure that every product that leaves our facility meets our high standards of quality and exceeds our customer’s expectations. Our product range includes aluminium extrusions, aluminium profiles, tubes, bars, rods, pipes, designed and manufactured with precision to meet the highest standards of quality and durability.

We cater to various industries such as Building & Construction, Automobile & Automotive, Electrical & Electronics, Solar, and consumer durables, providing them with high-strength, durable, and versatile aluminium extrusion products that can be used in a wide range of applications. Our mission is to provide exceptional customer service and build long-term relationships with our customers and suppliers, working towards sustainable growth and development.

As a leading aluminium section manufacturing company, we strive to create products that meet the evolving needs of our customers. Our commitment to quality, sustainability, and innovation has established us as a trusted name in the industry. We believe in providing exceptional customer service and strive to meet our customer’s expectations.

We looks forward to serving you and building a long-lasting relationship with you. Contact us today to learn more about our high-quality aluminium products and services.

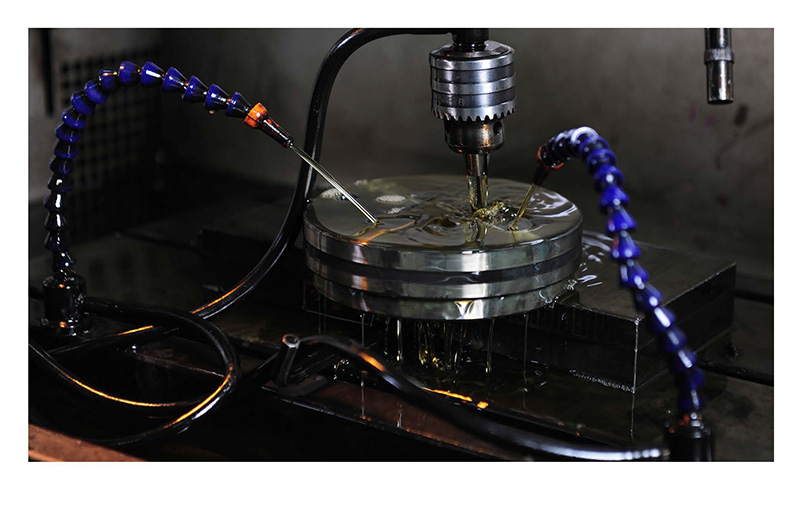

A technician pulls a round-shaped die from a warehouse or machines it from H13 steel and preheats it over it over 400 degree Celsius. Preheating the die ensures the metal flows evenly while maximizing its life span. After preheating the die, the technician loads it into an extrusion press.

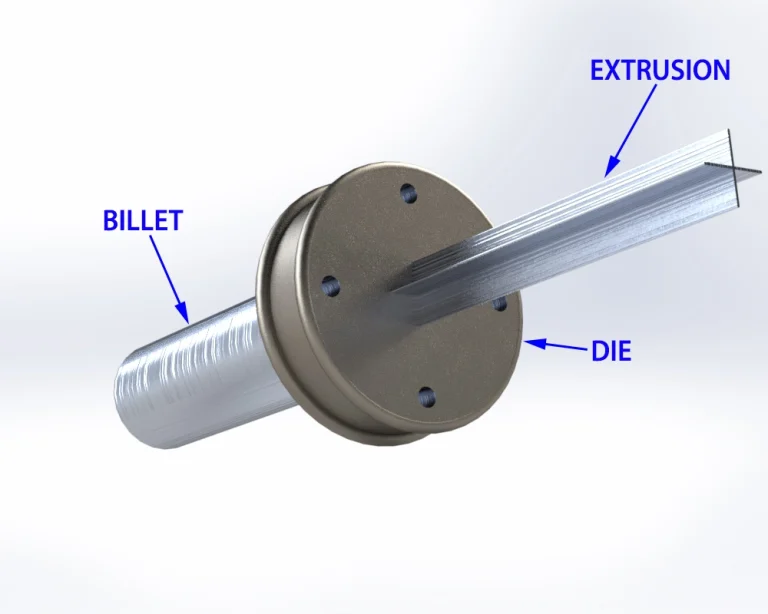

A billet is a solid, cylindrical aluminum alloy block. After heating and loading the die into the extrusion press, a technician cuts a billet from a long aluminum alloy log. Next, the technician preheats the billet between 400 and 500 degrees Celsius, giving it sufficient malleability for extrusion without liquefying it.

After preheating the billet, a machine transfers it to an extrusion press. The machine applies a release agent or lubricant to the billet and extrusion ram to prevent them from adhering to each other, and then it loads the billet into the extrusion press.

After the billet enters the extrusion press, a hydraulic ram applies pressure to push the billet into the extrusion press’s container. The ram can apply up to 15,000 pressure tons to move the billet into the container, and the billet material expands to fill the container’s walls.

The aluminum billet material presses against the die as it fills the extrusion container, and the continual pressure eventually pushes the billet material through the die’s opening. The material emerges in the shape of the extrusion die.

A puller grips the aluminum extrusion as it comes out of the die and guides it across a runout table. Fans or a water table cool the extrusion as it moves along the table through a process known as quenching. While this cooling process reduces the extrusion’s temperature, it does not entirely cool until later in the process.

As an aluminum extrusion extends across a runout table’s entire length, a hot saw shears it. Shearing the extrusion cuts and separates it from the extrusion equipment and process. After the saw shears the extrusion, the runout table transfers it to a cooling table. The extrusion remains on the cooling table until it reaches room temperature.

Extrusions twist naturally during extrusion, so a technician moves them to a stretcher. The stretcher mechanically grips each end of the extrusion and pulls it in opposite directions until it’s straight and meets specifications.

After the extrusion straightens and hardens, it moves to a saw table. At this stage, the extrusion’s properties have a T4 temper or hardness. The saw table cuts the extrusion to a pre-specified length, and a technician moves the extrusion to an aging that increases the extrusion’s temper from T4 to T5 or T6.

Technicians enhance an extrusion’s properties via heat treatment after it reaches the proper hardness. Following heat treatment, technicians apply surface finishes to increase corrosion prevention and polisy the extrusion’s appearance. Technicians may also perform fabrication operations such as cutting, punching, deburring, machining or drilling to achieve the desired dimensions.

| Process | EXTRUSION - Auto |

|---|---|

| Present Production | 2400 MT Per Month |

| Spare Capacity | 800 MT Per Month |

| Maxi. Weight Of Single Piece Casting | Few Grams to 50 Kilogram |

| Material | 1XXX, 2XXX, 3XXX, 4XXX, 5XXX, 6XXX, 7XXX & Special Al. Alloy |

| Inspection & Testing Facilities | Spectro Analysis, Mechanical Testing, Hardness Testing's, Impact Testing’s, Micro Tests, Coating & Anodize plant, All NDT Like RT, UT, MT, DT Etc. |

| Sector To Supply | Building & Construction, Automobile & Automotive, Aerospace, Defence, Electrical & Electronics, Lighting, Solar Industries, Marine, Medical, Rail & General Engineering Industries |

Aluminum extrusion is a manufacturing process that uses pressure to force aluminum through a die to create aluminum parts.

Aluminum extrusions are typically made from aluminum alloys, such as 6061 and 6063. These alloys are often strengthened by adding magnesium, silicon, chromium, iron, titanium, zinc, and copper.

At VG Engineering, We are fully selecting high-quality billets, properly preparing the extrusion die, maintaining consistent press settings, closely monitoring the cooling and quenching process, performing regular dimensional checks, and utilizing in-process and final product inspections to identify and address any deviations from specifications